Automotive & Industrial

One source of truth for sales data

Logio proposed an optimal data management approach and integrated Power BI into SKF’s IT landscape.

Outcome

Unified reporting with standard templates, clear ownership, and higher data quality delivered a smooth implementation.

More than

0 million records managed

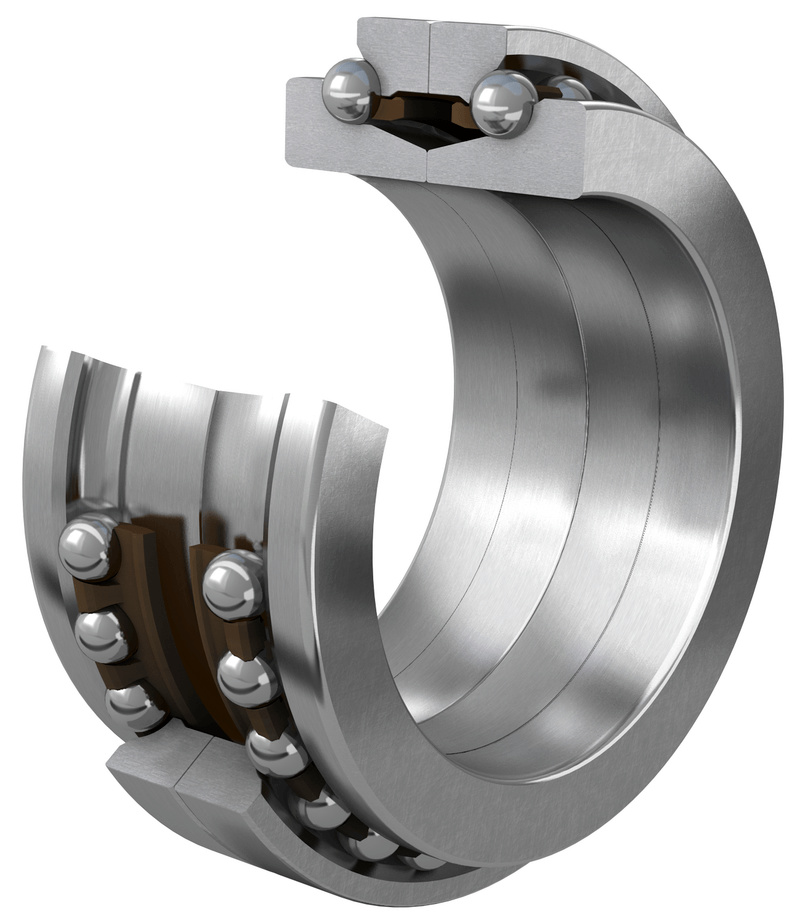

About SKF

SKF is a global Swedish manufacturer of bearings, seals, lubrication systems, condition monitoring and related services, founded in 1907 and headquartered in Gothenburg. It serves industrial and automotive customers worldwide.

Net sales: SEK 98.7 billion

Employees: 38,743 (2024 headcount)

Headquarters: Gothenburg, Sweden

Initial challenge

Sales data in the data warehouse reached gigabytes in size and required more efficient use and governance.

Project goal

Establish one source of truth with standardized reporting in Power BI, integrated into SKF’s IT structure.

Solution

From data warehouse to governed BI

Logio shared BI best practices and designed a governed reporting layer in Power BI, then integrated it with SKF’s existing IT environment.

Solutions implemented

KPI Design & Performance Monitoring

Technology Integration & Handover

Data Visibility & Accessibility

Impact

Reliable reporting on a governed, scalable BI platform

One source of truth established

A single governed data model for sales.

Standardized reporting

Reusable templates aligned how teams consume insights.

Better data quality and ownership

Roles and responsibilities clarified.

Seamless integration

Power BI connected to the existing data warehouse and IT stack

Scalability proven

Solution handles 100 million records in production.

Turn your data into reliable decisions

If your reporting is fragmented, we can help you create one source of truth and integrate Power BI with your data warehouse. Let’s discuss what a governed BI setup could deliver for you.

We tackled many supply chain challenges

Supply system implementation for an automotive production line

New supply system for an automotive production line that connects five information systems, reduces inventory in production and speeds up material delivery to the line.

Lower inventory levels in production

Shorter delivery time from warehouse to production line

Stable integration with five existing information systems

Ergonomics‑led productivity for a steel processor

Lean housekeeping and ergonomic improvements lifted productivity fast and set conditions for healthier, more stable operations.

+10 % labor productivity in 2 months

Up to –30 % long‑term sickness expected